Tecfluid manufacture instruments for measure flow and level in their factory located in beautiful Sant Just Desvern, in Barcelona Spain. The factory has been designing and manufacturing a wide range of Flowmeters since 1974, including Variable Area, Target Disc type, Electromagnetic, Positive Displacement, Turbine and Ultrasonic flow measuring instruments.

Click to watch Tecfluid’s impressive company video.

Variable area flowmeters, or as some like to call them Rotameters, are a very simple type of Flowmeter, but are very effective at measuring the flow of liquids, gases or steam. They are one of the most affordable methods of determining the Rate-of-Flow, as a purely mechanical Flowmeter. These Flowmeters do not Totalise the volume, but only show the rate in Litres per Hour (LPM), or whatever your preferred measuring units would be, as they can be scaled accordingly.

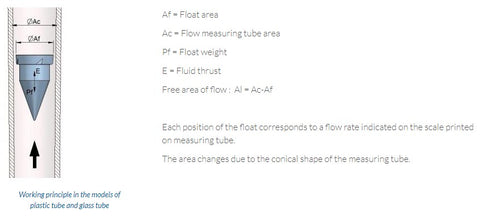

The working principle of this type of flowmeter consists of a float inside a conical shaped clear measuring tube. Installed vertically, the process media flows up through the tapered tube, lifting the float to a position where there is adequate free area around it to let the flow stream pass.You view the flow rate reading against the scale as the float hovers over its range.

The pressure drop remains constant over the entire flow range, as it relates to the floats weight and size, and the fluids density. This is why this type of flow measurement is referred to as Variable Area.

Some advantages of using Variable Area Flowmeters are you can use them on gases and liquids.

The design of them is simple and this keeps them economical to use in many applications. They are very easy to install, and they do not require power to operate.

Some disadvantages might be seen as they don’t have a high accuracy and they do require specific calibration for the process fluid or gas they are being used on.

The Flow Tubes need to be installed in the vertical position, with flow flowing upwards, through the flow tube. We have alternate Flowmeters if this type of installation isn’t suitable.

Click to read the Installation and Operating Manual for our Plastic Tube Flowmeters.

Our Plastic Tube Flowmeters are stocked in sizes ranging from ½” (15 mm) right up to 3” (80 mm), typically with Threaded End Union Connections. The standard material of the ends connections is PVC, but alternate process connection types (Solvent or Flanged) and materials (Polypropylene or stainless steel) are all options that are available on request.

We can also fit Limit Switches, for flow alarming and control to these Plastic Tube Flowmeters.

The limit switch is adjustable, allowing you position it wherever you need an alarm contact.

We can supply our Tecfluid Flowmeters specifically calibrated for any fluid or any gas type. Applications such as compressed air, or any gas for that matter, can be calculated and sized to suit your exact requirements by our technical team. By knowing your expected flow rate, the pressure the gas will be under, and what the gas type is, allows us to be very specific with the meter for your process.

Many industry sectors, including water treatment and purification, gas processing, the control and measurement in research laboratories, machinery installations, refrigeration and HVAC applications, the chemical processing and manufacturing industries… all can use, and do use, the ever-reliable Variable Area Flowmeter.

Ask us today about how they could be used to measure your flow.

Follow the links to check out our PSM and PS Clear Plastic Tube Flowmeters.